The Role of Precision Machining in Medical Device Manufacturing

From surgical instruments to life-saving implants, the components used in medical devices must meet rigorous standards to ensure safety, reliability, and functionality. Behind the scenes of this high-stakes industry lies precision machining, a manufacturing process that enables the creation of intricate and highly accurate parts essential for modern healthcare.

We specialize in precision machining for the medical industry, helping our customers bring innovative devices to market with the highest levels of quality and performance.

1. Meeting Tight Tolerances for Safety and Reliability

Medical devices often function in environments where even the smallest error can have significant consequences. Precision machining ensures that components are manufactured to small-level tolerances, allowing them to perform flawlessly under critical conditions.

For example:

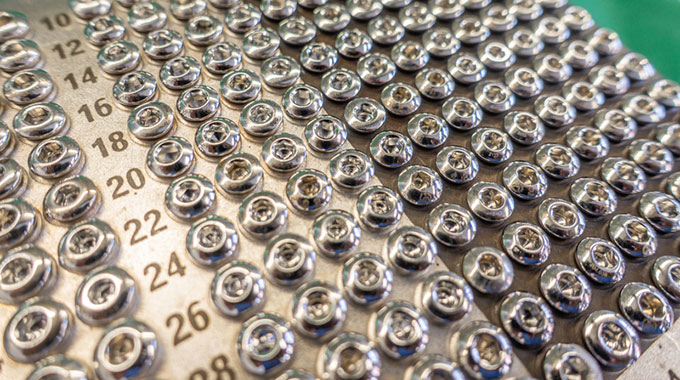

- Implants such as buttons for shoulder and knee surgeries must fit perfectly within the human body to ensure comfort and functionality.

- Surgical instruments require extreme accuracy to perform delicate procedures without harming surrounding tissue.

At Criterion Tool, our state-of-the-art CNC machines and meticulous quality control processes guarantee that every part meets the stringent requirements of the medical industry.

2. Working with Biocompatible Materials

Medical device components often require materials that are biocompatible—safe to use within the human body—or capable of withstanding sterilization processes. Precision machining excels at handling these specialized materials, which include:

- Titanium – Commonly used for implants due to its strength, lightweight properties, and biocompatibility.

- Stainless Steel – Ideal for surgical instruments because of its durability and resistance to corrosion.

- Advanced Polymers – Used in applications like catheter components and implantable devices for their flexibility and chemical resistance.

Our expertise at Criterion Tool allows us to machine these materials with precision, ensuring each component’s performance and compliance with medical standards.

3. Enabling Innovation in Medical Technology

As healthcare evolves, the demand for innovative devices continues to grow. Precision machining is a driving force behind this innovation, enabling manufacturers to create complex components for cutting-edge technologies.

Key applications include:

- Minimally Invasive Surgical Tools: Smaller, more precise components enable less invasive procedures, reducing patient recovery times.

- Wearable Medical Devices: Precision machining supports the development of compact, high-performance devices for monitoring health conditions.

- Robotics and Automation: Machined components are critical for robotic surgical systems and automated diagnostic equipment.

By partnering with Criterion Tool, manufacturers can transform their innovative concepts into high-quality, reliable medical devices.

4. Prototyping and Small-Batch Production

The journey from concept to production often begins with prototyping, where precision machining plays a pivotal role. Our ability to produce small-batch, high-precision components helps medical device companies:

- Test and refine new designs.

- Minimize material waste during development.

- Accelerate the time-to-market for innovative products.

We work closely with customers to optimize their designs for manufacturability, ensuring prototypes are both functional and scalable for production.

5. Compliance with Regulatory Standards

The medical industry is one of the most heavily regulated sectors, with strict standards for quality and safety. Precision machining helps manufacturers meet these standards by delivering consistent, high-quality components that comply with requirements such as:

- FDA Regulations – Ensuring materials and processes meet safety and performance guidelines.

- ISO Standards – Adhering to international quality standards for medical devices.

- Traceability – Maintaining detailed documentation for every component produced.