What is Precision Machining? A Comprehensive Guide

When you think about the tools and technologies that power industries like aerospace, medical devices, photonics, and defense, you might not immediately think about the parts behind the scenes—the small, intricately designed components that make it all work. Yet, these components are critical, and creating them requires an advanced process known as precision machining. At Criterion Tool, precision machining is not just a service—it’s a cornerstone of the innovation and reliability our customers depend on.

Understanding Precision Machining

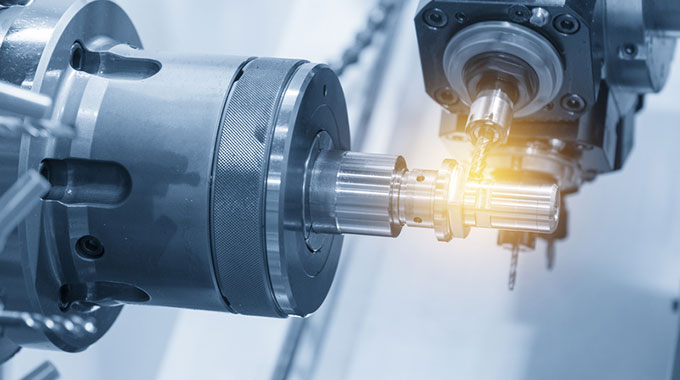

Precision machining refers to the process of shaping raw materials—such as metal or plastic—into highly accurate and complex components with tight tolerances. This meticulous process often involves advanced equipment like computer numerical control (CNC) machines, lathes, and mills, which are programmed to meet exacting specifications.

From medical implants to aerospace parts, precision machining creates components where even the smallest deviation from the design could mean failure in the field.

How Precision Machining Works

Design and Engineering

The journey begins with a detailed design, often created using CAD (Computer-Aided Design) software. This digital blueprint specifies the dimensions, tolerances, and materials needed for the part.

Material Selection

Choosing the right material is essential. At Criterion Tool, our materials have a vast range including titanium and stainless steel to specialized plastics, ensuring the material aligns with the part’s function and environment.

Machining Process

The design is fed into CNC machines, which perform processes such as:

Turning: Removing material from a rotating workpiece to create cylindrical shapes.

Milling: Cutting shapes and features into a stationary workpiece.

Drilling: Creating extremely precise holes.

These machines operate with micron-level precision, ensuring that the final product matches the design exactly.

Finishing and Inspection

Once the machining is complete, the parts undergo finishing processes like deburring, polishing, or coating to ensure functionality and aesthetics. Every component is rigorously inspected to confirm it meets the required tolerances and standards.

Why Precision Machining Matters

High Tolerance for Critical Applications

Precision machining is essential for industries where components must perform flawlessly under extreme conditions. For example:

In medical devices, precision-machined parts ensure the safety and efficacy of tools like surgical instruments and implants.

In aerospace, the slightest error in a machined component could compromise the safety of an aircraft.

Cost-Effective Manufacturing

Although precision machining might seem costly upfront, it reduces long-term costs by ensuring components are durable, reliable, and fit perfectly the first time. Design for Manufacturing (DFM) helps prevent the need for rework or replacement down the line.

Driving Innovation

Precision machining enables the creation of prototypes and custom parts, helping industries push the boundaries of what’s possible. Whether it’s miniaturized components for photonics or lightweight, high-strength parts for aerospace, precision machining is the foundation of progress.

Why Choose Criterion Tool for Precision Machining?

As a woman-owned, precision-focused machining shop based in Cleveland, Ohio, Criterion Tool brings decades of expertise to every project. We specialize in crafting small, complex parts for industries where precision isn’t just a preference—it’s a requirement.

Here’s what sets us apart:

Expertise Across Industries: From photonics to medical devices, our team understands the unique needs of each field.

Advanced Equipment: Our state-of-the-art CNC machines deliver the tight tolerances your projects demand.

Commitment to Quality: We rigorously inspect every part to ensure it meets or exceeds specifications.

Collaborative Approach: We view manufacturing as the ultimate team sport, working closely with our customers to deliver solutions tailored to their needs.

Partnering with Criterion Tool

At Criterion Tool, we’re not just machining parts; we’re solving problems and creating possibilities. Whether you’re developing a new product or refining an existing design, our precision machining services can help you bring your vision to life.

Let’s start the conversation. Request a quote today and discover how Criterion Tool can deliver the precision and expertise your project requires.